Situation

Operating conditions changed several times, enormous demand for naphtha

Single seal HRS with DiamondFace enables high cost savings of API Plan 32

Operating conditions changed several times, enormous demand for naphtha

Highly viscous crude oil, reduction of the flush fluid by 70 %

Single seal HRS with DiamondFace from EagleBurgmann

The state-owned company Petróleos de Venezuela S.A. (PDVSA) operates the Junin oil field in the Venezuelan Orinoco Belt. Each day, 22 multiphase pumps deliver 95,000 barrels of crude oil directly from the wells in this 399 square kilometer area. Multiphase fluids place extreme demands on the pump seals.

Both shafts of the twin-screw multiphase pumps from a well-known manufacturer were each equipped with two single seals in hard-soft material combination from EagleBurgmann. The seals were lubricated and cooled according to API plans 32 and 62. The system had worked perfectly for years, the seals only needed to be overhauled every 24 to 36 months.

However, the consumption of naphtha for flushing the seals was extremely high in Plan 32. 45 liters per pump and minute were injected in the pump and pipelines – 11.25 liters per seal and minute. Per day and pump this resulted in a total of 407.55 barrels, i.e. about 64,800 liters per day and pump. For all 22 pumps, that was 1.43 million liters of naphtha every single day!

In the course of about three years, the operating conditions and the nature of the multiphase fluid changed considerably. Now, the pumps had to handle a multiphase fluid comprised of extra-heavy crude oil with a higher proportion of sand, produced water and gas. The result was a reduction of the seals’ service life down to three months. This changed operational situation forced the operator of the oil field to request a new sealing concept that also would significantly reduce the consumption of naphtha as a flush fluid.

It was an ambitious goal: The seals should also function perfectly with 70 % less flush fluid in the API Plan 32, i.e.: 14 liters per minute for all four seals in one pump! If this were feasible, the cost of naphta would be reduced by roughly 10,000 US dollars per pump per day.

The varying composition of the multiphase fluid made the task even more challenging: The solid content is up to 20 %, the gas content is 30 % to 90 % and the water content can come to 80 %. Another complicating factor is that the composition of the fluid is constantly changing and unpredictable. In terms of savings calculations, it also had to be taken into account that 60 % of the naphtha can be recycled while the remaining 40 % cannot be reused.

The customer also insisted on a single mechanical seal because a dual pressurized seal would require a maintenance-intensive barrier fluid system. Not only would the capital expenditure be high to retrofit or upgrade the existing pumps, the maintenance risk in the unmanned stations was prohibitive as well. This made suitable materials for the new sealing concept all the more important.

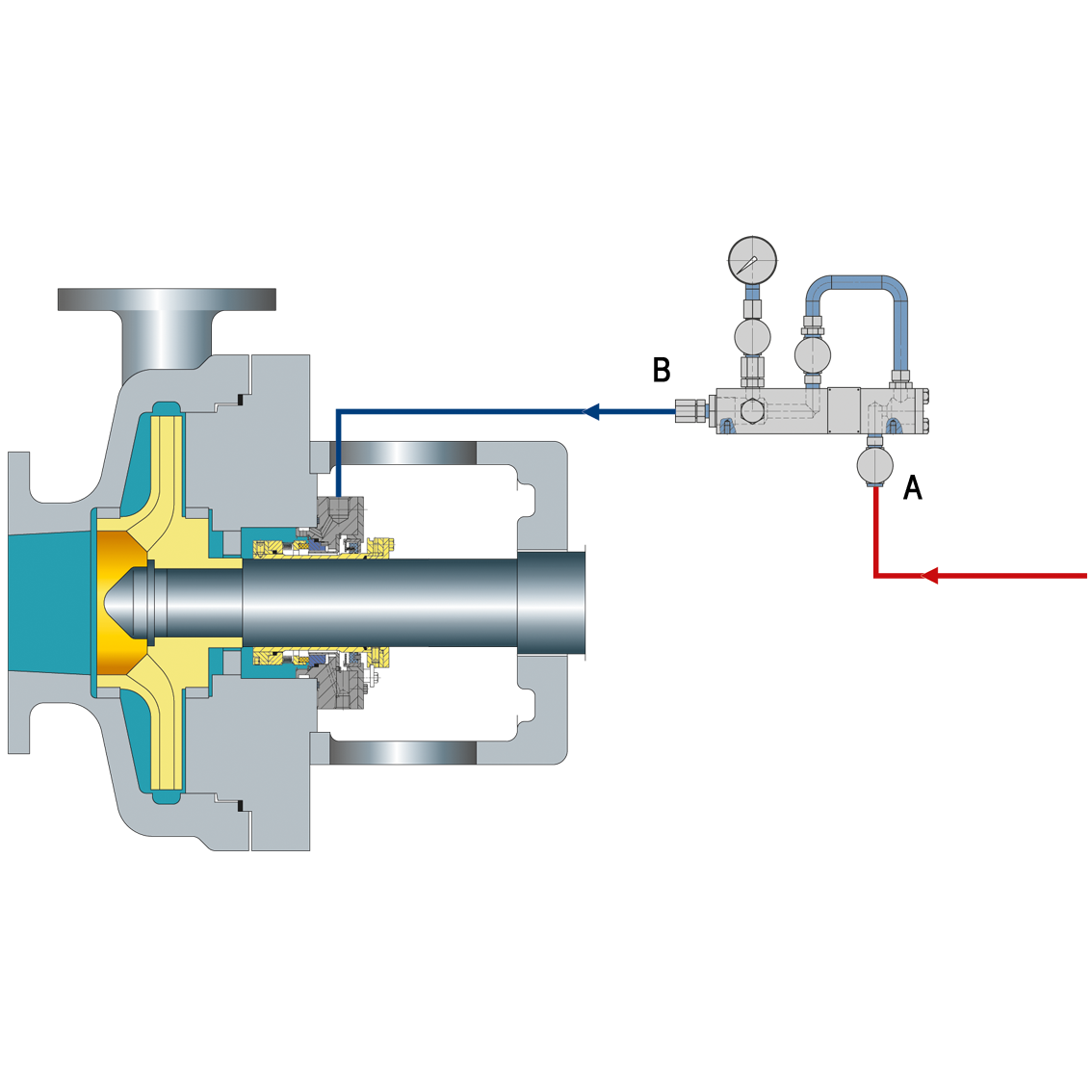

After detailed investigations, EagleBurgmann selected an extremely robust mechanical seal of the HR series which was specifically developed for use in solids-laden media without external flushing or product circulation. The seal faces are made of a hard-hard combination of silicon carbide which cannot be damaged by the abrasive effect of the sand particles. Additionally, the design of the seal makes it particularly robust.

With a view to the reduced quantity of flush fluid and the poor lubricating properties of the multiphase fluid due to the quantities of sand, water and gas, EagleBurgmann installed a further safety protection and additionally treated the sliding faces of four seals for a pump with DiamondFace technology. Thus, the surfaces of the silicon carbide seal faces received a microcrystalline layer of artificially manufactured diamond. This layer makes the surfaces extremely wear-resistant and capable of dry running. Moreover, heat is dissipated very well.

The field test for all 22 pumps started in 2014, one of which contained the DiamondFace seals. After ten months of operation, the operating conditions changed again. Instead of naphtha, the seals were now supplied with a mixture of light crude oil of poor quality and higher viscosity. The consequence: 21 pumps had to be shut down due to malfunctions in the seals. The failure analysis showed that a mixture of crude oil products had clogged the seals such that the flush fluid could not penetrate this resistance, the seals remained unsupplied and then failed.

Only the pump with the DiamondFace seals ran for another eight months without interruption. When it was shut down for operational reasons after a total of 18 months, EagleBurgmann examined the four seals. Large quantities of extra-heavy crude oil, naphthenes and sand had accumulated in the seal cavity, especially in the flush ports, which means the seals worked without adequate flushing over a longer period of time. However, the sliding surfaces were in excellent condition.

All in all, one and a half years of field testing showed that robust single seals with DiamondFace withstood a supply with 70 % less flushing fluid and operated reliably in a very harsh environment. Minimizing the consumption of naphtha and reduction of cost are possible. If the customer equipped all 22 twin-screw pumps with DiamondFace seals from EagleBurgmann, he could save approximately 81 million US dollars every year.

Operating conditions

Between June 2017 and March 2019 the Hengli Group constructed an integrated refining and chemical complex in the Chinese harbor town Dalian where 20 million tons of crude oil are processed every year. EagleBurgmann advised the company Hengli concerning the selection of mechanical seals and supply systems for the whole plant and supplied more than 95 % of the components in use.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Things get hot in rotary kilns, very hot in fact. In the production of cement, for example, the thermometer measures more than 1,000 degrees Celsius. Sealing systems from EagleBurgmann, a company of the Freudenberg Group and EKK, make sustainable contributions to environmental protection, energy efficiency and process reliability under these "fiery" high-temperature conditions.

Our modern civilization is quite literally built upon cement. Today, building materials made from cement are used in buildings, roads, bridges, dams etc. Cement production is a heat-intensive process and causes thermal expansion in duct systems. To compensate this, Indian cement producer Ramco Cement needed fabric expansion joints with a diameter of several meters for two of their plants. On the basis of a close collaboration, EagleBurgmann was able to design components that increase the efficiency of the plant in the long run.

Seals are a risk factor in the production of liquid crystals. If there is even the slightest contamination of the liquid crystals, this will later affect the image quality of the display. Read on to see which sealing solution Merck KGaA uses in paddle dryers for the production of liquid crystals.

Cruise liners have to reduce their sulfur emissions in Emission-Controlled Areas (ECAs). To accomplish this, light fuel oil is used in coastal regions - with significant consequences for the ship's fuel supply.